Frequently Asked Questions + Known Bugs, Workarounds, and Limitations

THIS IS STEP 6 of the 6 steps to get started -- as you work with SCM Globe you will need answers to the seven FAQs, and workarounds for a few known bugs and some software limitations. Please read the FAQs, the Known Bugs, and Software Limitations listed below.

If you are using a Corporate, Government, or Military issued computer, there may be extra security software installed that interferes with the operation of SCM Globe. Check with your technical support group. Or use your own personal laptop.

Chrome, Edge, Firefox and Safari work with SCM Globe. If you use a browser other than those listed here you may have problems. You can download a free copy of Chrome or Firefox by going to the websites of those providers:

- Chrome - https://www.google.com/chrome/browser/desktop/

- Firefox - https://www.mozilla.org/en-US/firefox/channel/

If you are using one of these browsers and still having problems, your computer may have extra security software that causes problems with SCM Globe.

Delivery vehicles occasionally miss deliveries. The frequency of missed deliveries depends on the frequency of deliveries and the time it takes for a vehicle to travel its delivery route. More frequent deliveries made by vehicles traveling on longer routes result in higher rates of missed deliveries (just like in the real world). Because of missed deliveries it is necessary to have some extra “safety stock” inventory at facilities (just like in the real world) to keep them going when this occurs. And sometimes there will even be two deliveries made when only one was expected, so you need to have a bit of extra storage space available at facilities to handle unexpected deliveries. To improve scheduling of vehicles on routes see a full explanation in “Delivery Schedules Do Not Always Work Perfectly”.

You will also notice your simulation results do not always match exactly with results of others working on the same case study. This is because of small differences in where you place a facility or how you define routes or vehicles or times between departures. The more adjustments and changes you make to your supply chain model (even very small ones), the more your results will differ from others who do similar but not exactly identical things in their models. Learn more about this in "The Butterfly Effect".

There are many possible ways to respond to the challenges in each case study. As you work with cases you may find better ways to solve problems than what others have found. Do not just blindly follow one way of responding to the case challenges - explore and try out different ideas. The simulations show you what works best.

"Day 0" calculations start a simulation - There are initial calculations made by the simulation engine that affect beginning amounts of on-hand inventory for some products at some facilities. These initial calculations create the “Day 0″ starting point for the supply chain at the beginning of a simulation:

- On Day 0 the facilities that have daily demand for a product have that daily demand amount subtracted from their on-hand inventory, so when you open a new facility you must have enough on-hand inventory to cover at least two days demand.

- Also if there are routes originating at a facility where products are picked up from other facilities and returned to the facility, then the amount(s) of picked up product(s) are added to on-hand inventory.

Normally, you do not need to worry about these Day 0 calculations. But if you want to learn more or compensate for these initial calculations, you can read about them in "Tips for Building Supply Chain Models" - scroll down to the heading titled "Day 0 Calculations and Adjustments".

You have to assign a product to a facility before you can deliver that product to the facility - If you are setting up a route and can’t deliver a particular product to a particular facility because you don't see it in the drop down box for that facility, then you have to go back to the facility (in the Facility menu) and assign that product to the facility. You can only deliver products that are already assigned to a facility. To assign a product to a facility, you add the product to the facility and give it an on-hand amount, and/or amounts for production per day and demand per day. Any or all of these amounts can be set to zero.

NOTE: Because SCM Globe is a web-based application, changes to your supply chain model in the Edit screen do not update in the Simulate screen until you go to the Simulate screen and click the browser refresh or the “Reload Supply Chain” button. And remember, if you go back to the Edit screen and make more changes, you must click browser refresh again on the Simulate screen to include those additional changes.

Drag and drop the white globes that appear along the route line of the ship when it is first created. Click on each white globe along the route as needed and drag it to change the route line to better follow the route you want. If you have an existing route for a ship and you want to change it, select the route in the edit screen and click on "Edit route line" in the lower left side of the route dialog box. When you do this you will see white globes appear along the route line. Drag and drop them as needed and then click on "Stop edit" and click the "Update" button. Because the route is no longer a straight line it will also have more distance than the initial straight line route. Distances shown on ship routes are ROUND-TRIP. Shipping routes in the real world usually take the shortest path between port of origin and port of destination while also staying on water and away from land.

Airplane routes are also drawn as straight lines between starting and destination facilities, and distances shown are ROUND-TRIP . You can usually leave airplane routes as straight lines because airplanes can fly over sea and land. Sometimes you may want to modify these straight lines to avoid restricted airspace (such as North Korea) and you would modify the initial route the same way that ship routes are modified. See more information about routes in Tips for Building Supply Chain Models - scroll down the the "Routes" section of that page.

EDIT SCREEN may load slowly or load only part of a supply chain. This may happen if you are using a slow Internet connection, or if you using a less powerful computer to work on a big supply chain model (more than 25 - 30 facilities, vehicles, and routes):

- The screen appears to freeze, it remains blank, or shows only part of the supply chain. It may take up to 10 seconds to load the full supply chain. But after 10 - 12 seconds if the supply chain does not draw completely, CLICK BROWSER REFRESH!

- Problems may also occur if you have special security software installed on your PC. Normal anti-virus and security software is not a problem. But if you are using a computer supplied by your company, or a government/military organization, it may have special security or anti-virus software that is blocking SCM Globe - check with your technical support staff about this.

- When in doubt - CLICK BROWSER REFRESH!

SIMULATE SCREEN can freeze and remain grayed out for three reasons:

- You have a slow Internet connection or bandwidth congestion and it may take 10 - 20 seconds to fully load the Simulate screen. If the screen continues to stay grayed out, CLICK BROWSER REFRESH!

- A vehicle does not have a route - all vehicles need one or more routes assigned to them or the simulation will not run. You will see an error message and even after you click "OK" to close the error message, the Simulate screen will remain grayed out. Close the browser tab with the still grayed out SIMULATE screen. Go back to the EDIT screen and assign routes to all vehicles, or delete any vehicles without assigned routes. Then click the "Simulation" button again to open a new SIMULATE screen.

- Your supply chain model (.json file) is damaged - continuing to get error messages about a vehicle missing a route after you make these fixes means your supply chain file is damaged. You must restore your supply chain model from an earlier saved backup copy (see "Saving Copies of Supply Chain Models" in Table of Contents on right side of this screen). If you did not make any backup copies, then load a new copy of your supply chain model from the library, and recreate the changes you made to your model.

Depending on the power of your computer (CPU and memory) you may notice a slowdown in performance. SCM Globe runs partly on our servers in the cloud and partly in the browser on your PC or laptop or tablet. Response time is affected by the speed of your Internet connection (at least 3 bars of wifi signal strength) combined with the power of your PC. SCM Globe runs best on newer computers with fast CPU chips, more memory, and fast Internet connections.

Set "Speed" option to "Fastest" on the Simulate screen. In the upper right side of the Simulate screen see the option to set the speed for the simulation. Speed settings go from Slow and Medium to Fast and Fastest. You can change the speed at any time before or while a simulation is running.

Have one browser tab open for the EDIT screen, and one browser tab for the SIMULATE screen. After opening the browser tab with the SIMULATE screen, flip back and forth between the two tabs to edit your supply chain model and run simulations. Do not have multiple SIMULATE tabs open on your browser. The more SIMULATE tabs open, the slower your simulations will run.

Make sure no other applications are running on your PC except your web browser and SCM Globe. Depending on the power of you computer, running other applications at the same time (such as email, word processing, Facebook, YouTube etc.) can cause your simulations to run slowly. See more ideas for speeding up your simulations and addressing other problems here: SPEED UP - UNFREEZE - DEBUG Your Simulations

NOTE: Simulations generate hourly and daily performance data for a supply chain. Simulations are expected to cover 30 to 90 day periods. If you run a simulation covering a period of a year or more you may encounter an "out of memory" error because simulation data is stored in the memory of your computer. There is no need to run simulations beyond 30 to 90 days.

And remember - if screens take longer than about 10 seconds to load, or if screens do not load completely, then CLICK BROWSER REFRESH!

SAVE BACKUP COPIES of your supply chain model from time to time as you make changes. There is no “undo”, but if a change doesn’t work out, you can restore from a saved copy. And sometimes supply chain models (.json files) become damaged and no longer work, so you want backup copies to restore from when that happens. Click "Saving Copies of Supply Chain Models" in the USER INTERFACE section of the Table of Contents on the right side of this screen (bottom of screen on smartphones).

IF YOU ENCOUNTER A PROBLEM not answered by the FAQs or Known Bugs and Workarounds shown below, please contact info@scmglobe.com with a description of the problem and ATTACH A COPY of your supply chain model (.json file). See the Table of Contents on the right side of this screen -- click on "Download and Share Supply Chain Models".

** IF YOU PURCHASED the BUSINESS EDITION: SCM GLOBE PRO — Please contact us (info@scmglobe.com) to activate the data import/export features, and the automatic modeling and reporting features of SCM GLOBE PRO. You can also schedule a one hour training session included with SCM GLOBE PRO.

[ Access this Online Guide by clicking “Help” in upper right corner of any SCM Globe application screen. ]

Known Bugs, Workarounds, and Limitations

Here's a list of bugs we're currently tracking, as well as workaround fixes for these bugs while we move toward resolution. There is also a short list of limitations due to the supply chain modeling logic we use.

As always, don't hesitate to get in touch with us if you're not finding what you need.

Get SupportBUG 1. Distances and times shown in route dialog boxes sometimes do not display correctly. When you create a new route it will show ROUND-TRIP distance and time. But sometimes distances and times for routes are displayed as ONE-WAY. This problem has been largely corrected but may still appear occasionally. Also, if an existing facility in a model is moved from its original position to a new position, it may continue showing old route distance and time numbers instead of new route distance and time numbers reflecting its changed position.

WORKAROUND -- This is only a display problem, the route data used in simulations is always ROUND-TRIP and is correctly updated so simulation results are accurate. If you delete the route displaying one-way or old distance and time numbers, and recreate it, the display will update and show correct route distance and time.

BUG 2. When you drag/drop a facility that has vehicles and routes and put it in a new location, it will redraw the routes associated with the vehicles at that facility, but two problems can occur: 1) Route distance display on re-drawn route does not update and continues to show the old route distance; 2) Some truck or railroad routes re-draw as straight lines instead of following roads.

WORKAROUND 1 -- Route distance is only a display problem, it can be fixed by deleting a stop on the route and adding the stop back to the route.

WORKAROUND 2 -- Remove incorrect straight-line routes and re-create them; they will follow roads correctly when you recreate them.

BUG 3. If you reduce the carry volume of a vehicle after you already assigned the vehicle to a route and defined the drop quantity of products on that route, it can result in the product drop quantity exceeding the reduced carry volume of the vehicle. When you first define product drop quantities it will prevent overloading a vehicle, but it does not check vehicle overloading again if you reduce the vehicle capacity. This can also happen if you increase the size of a product after drop quantities have been assigned.

WORKAROUND -- If this occurs, adjust the vehicle carry volume, or adjust the size of the product to fix this problem. This problem only occurs with volume, not with weight. If you reduce the max weight a vehicle can carry, or increase the weight of a product, this will be detected when you try to run the simulation. And if you reduce the storage capacity of a facility or increase the size of a product so that it exceeds the storage capacity of a facility, this error too will be found when you try to run the simulation.

Software Limitations

The modeling and simulation logic used by SCM Globe imposes some limitations on how the simulations operate and the results they produce. SCM Globe uses a discrete event simulation (DES) method with a fixed-increment time progression of one hour. Time in the simulations is broken into one hour increments, and the supply chain system state is updated according to the events happening each hour. Results are rounded up or down to the nearest hour. Thus, as the number of hours a vehicle takes to travel a delivery route decreases, the greater is the effect of these rounding errors. Limitations created by hourly rounding errors are listed below, along with suggested workarounds for managing those limitations. (NOTE: This problem is solved in the new Enterprise version by using one minute time progression increments.)

LIMITATION in Vehicle Modeling Logic: The SCM Globe simulation engine calculates hourly snapshots of the status of all the entities in a supply chain. Vehicle event times are the total of a vehicle’s delay between departure plus the route time for its delivery route (Vehicle Event Time = Delay Between Departures + Route Travel Time). As vehicle event times decrease to four hours and less, the probability of simulation engine hourly snapshots missing a vehicle event increases.

1. Vehicle cost and carbon calculations in simulations are calculated using a one hour time progression increment. That means travel times for vehicles are rounded up or down to the nearest whole hour even though actual travel times may be fractions of hours. This will affect calculations for vehicle operating cost and carbon generation. When vehicle event times are 4 hours or less rounding errors can increase from around 10% at 4 hours to 60% or more on routes less than 1 hour. On longer routes (4 hours or more) rounding errors decrease to around 5 % or less as route length and travel times increase. Also, rounding errors decrease over longer simulation periods (15 days or more).

- Adding a stop on a multi-stop route where it takes less than 1.5 hours for a vehicle to move between the added stop and the previous or next stop will cause vehicle operating costs and carbon to be noticeably under counted.

- Single-stop routes where the vehicle event time is 1.5 hours or less will show vehicle operating costs and carbon generation that is over counted by 10 to 80 percent as travel time decreases below 0.5 hours.

- WORKAROUNDS:

- Expand the timeline and make one day of a simulation equal half a day (12 hrs), or a quarter day (6 hrs), etc. See more about this in the section below titled “SIMULATION TIMELINE”

- Reduce the speed of vehicles so that travel times on routes are 1.5 hours or more. This can be done on single stop routes, but may not be practical on multi-stop routes.

- Facilities this close together can be modeled as a single facility with the combined attributes of the included facilities.

- WORKAROUND 1 - Reduce the speed of vehicles so that travel times on routes are 1.5 hours or more. This can usually be done on single stop routes, but may not be practical on multi-stop routes.

- WORKAROUND 2 - Facilities this close together could be modeled as a single facility with the combined attributes of the included facilities.

NOTE: The new Enterprise Edition of SCM Globe will use a one minute progression increment to fix this rounding problem and support more detailed modeling of facilities and operations.

2. Product delivery and product on-hand amounts remain accurate, regardless of time frames, all facilities will show accurate on-hand amounts of products unless limitation #3 shown below is in effect on one or more delivery routes.

3. Product deliveries on routes where vehicle Delay Between Departures + Route Travel Time = 4 hours or less are undercounted at an increasing rate (10 to 40 percent) as the total time drops below 0.5 hours.

- WORKAROUND 1 - Increase delay between departures for a vehicle so the route time plus the delay between departures is equal to four hours or more.

- WORKAROUND 2 - Shrink the simulation timeline to make one day equal half a day, or a quarter of a day. See more about this in "Tips for Building Supply Chain Models" - scroll down on the page to the major heading "Vehicles", begin reading the paragraph starting with "Limitation in Vehicle Modeling Logic..." Also see major heading "Simulation Timeline" for an explanation of scaling the timeline.

4. All vehicles begin their routes when a simulation starts - Usually this is not a problem, but if you want to model a supply chain where some or all vehicles wait for a number of days before departing on their routes, there is a way to do this. See how to do this in the online guide page "Tips for Building Supply Chain Models" - scroll down on the page to the major heading "VEHICLES", begin reading the paragraph starting with "Create a vehicle that waits before departing..."

5. Limitation in Route Modeling Logic - There is a limitation in the modeling logic used for creating multi-stop routes where products are picked up and dropped off at different stops along the route. This limitation and a workaround for the limitation is explained in the online guide page "Tips for Building Supply Chain Models". Scroll down on the page to the major heading "ROUTES", begin reading the paragraph starting with "A Limitation in Route Modeling Logic..."

6. Number of Entities (Products, Facilities, Vehicles, and Routes) in a Model - Current versions of SCM Globe and SCM Globe Pro run partly on the SCM Globe application servers in the cloud, and partly on each person's individual computer (desktop, laptop, tablet). The more powerful the computer and the more memory it has, the larger the number of entities that can be added to a supply chain model. Supply chain models containing more than 25-30 products, facilities, vehicles, and routes require computers with at least 16 GB and preferably 32 GB of memory and a suitably fast CPU. Models of 50-75 products, facilities, vehicles, and routes can be supported on such computers. See techniques for managing these limits in "Tips for Building Supply Chain Models".

7. Exporting Simulation Data - There will be problems exporting data from simulations that run for 60+ days. Most companies plan their business operations on a monthly (or weekly) basis. That is why SCM Globe focuses on 30 to 60 day simulations. Every month, or every week, a company updates its product demand forecasts and that leads to changes in production schedules and procurement rates. Which in turn leads to changes in vehicle assignments and delivery routes. So there is little value in running simulations beyond 60 days.

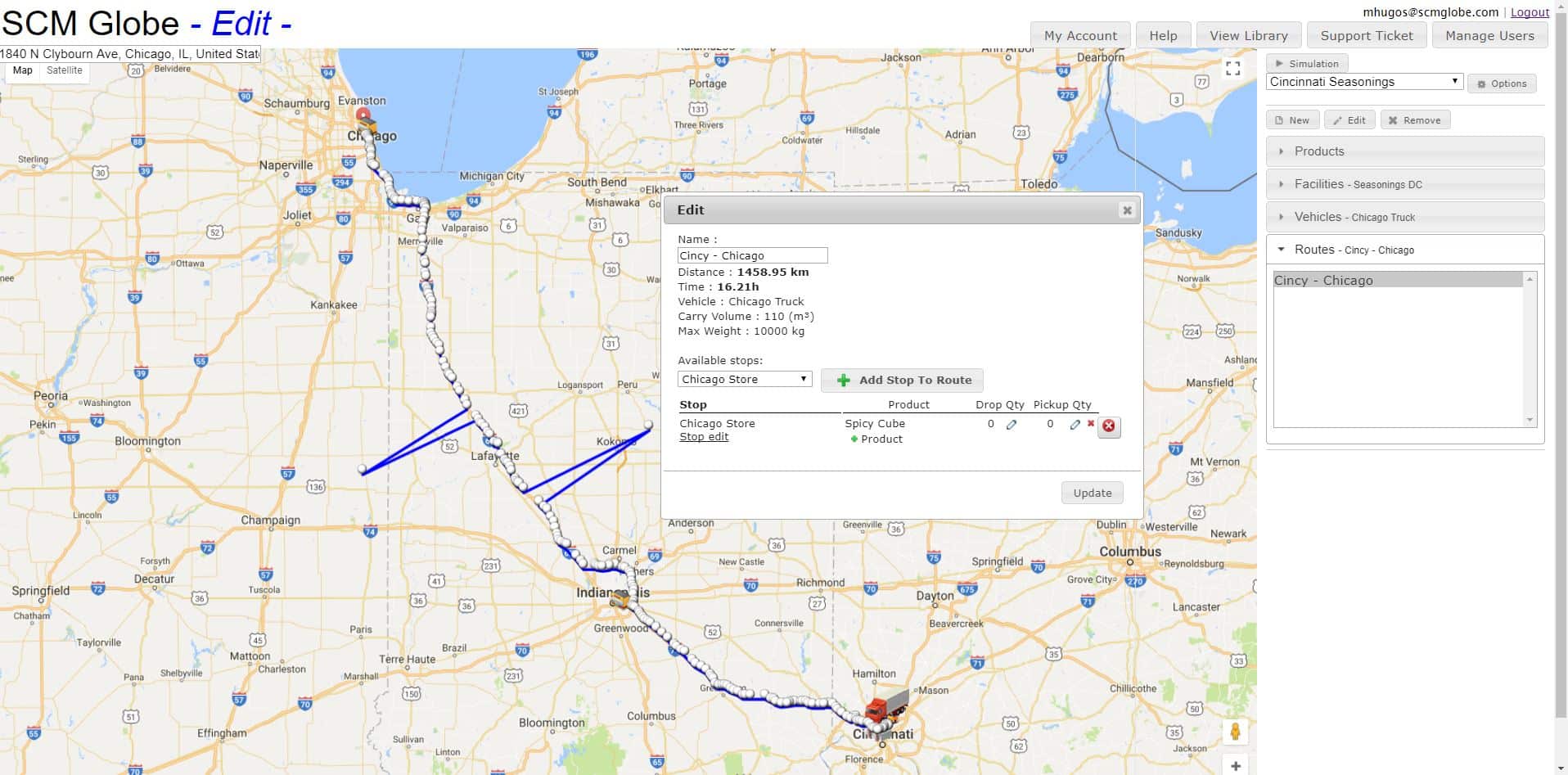

8. When you first create a truck route, you can drag/drop the route line to follow a different road other than the one first shown. But after you save the route, you can change only stops and product drops or pickup quantities. You cannot change the route line itself. When you click on "Edit route line" in the dialog box, it will display the truck route onscreen covered with hundreds of little white globes. If you drag and drop one or more of those white globes it will distort the route line in a manner shown in the screenshot below, but it will not enable you to drag-and-drop the route to follow a different road. To change routes of existing truck or railroad routes, delete entire route and recreate it.

(click on screenshot to see larger image)

(click on screenshot to see larger image)

Adjust Your Screen Resolution as Needed

Sometimes the display on the Edit or Simulate screen is so big you cannot see the entire screen: display graphs on the right side of the screen; or numbers overwrite the names of the facilities and you cannot read either the numbers or the names. This happens mostly on laptops or tablets. An example of this is shown in the screenshot below:

TO FIX THIS PROBLEM: Adjust the zoom level in your browser -- set it to a lower zoom level. On the Chrome browser look in the top upper right corner of the browser and see three dots stacked on top of each other (in the Edge browser it will be three dots side by side, on Firefox it will be three short lines stacked on top of each other). Click on them as shown by arrow 1. A submenu opens up; see “Zoom” about half way down the submenu as shown by arrow 2. To the right of Zoom see your browser zoom level; if it is set to 100 or more try reducing it to 90 or less by clicking on the minus sign (-) next to the zoom number. Reduce the zoom level until entire screen displays in your browser.

IF YOU ENCOUNTER A PROBLEM that is not answered by these FAQs, please contact info@scmglobe.com with a description of the problem and ATTACH A COPY OF YOUR SUPPLY CHAIN MODEL (.json file) so we can load your supply chain model and investigate your problem. To attach a copy of your model (json file) read instructions here -- Download and Share Supply Chain Models.

SAVE BACKUP COPIES of your supply chain model from time to time as you make changes. There is no “undo”, but if a change doesn’t work out, you can restore from a saved copy. And sometimes supply chain model files (json files) become damaged and no longer work, so you want backup copies of your supply chain to restore from when that happens.

NOTE: The academic version of SCM Globe supports supply chain models containing up to 15 – 20 products and a similar number of facilities, vehicles and routes. Models exceeding these limits will run slowly and experience other problems. See “Tips for Building Supply Chain Models” for ways to work with these limits and other useful techniques you will need when you build new supply chains or add new products, facilities, vehicles and/or routes to existing supply chains.

STUDENT ACCOUNTS DEFAULT TO 90 DAYS FROM DATE OF PURCHASE — if your semester is a few weeks longer, then send an email to: info@scmglobe.com. State your name, the email address you used to register, your school, and your semester end date. We can extend your account to cover your entire semester.

Key Points to Remember

Here are some things to keep in mind about SCM Globe to help ensure you have a trouble-free and satisfying user experience.

Don't be afraid to ask questions. We value your feedback, and we look forward to hearing from you.

Get in Touch[ Access this Online Guide by clicking “Help” in upper right corner of any SCM Globe application screen ]

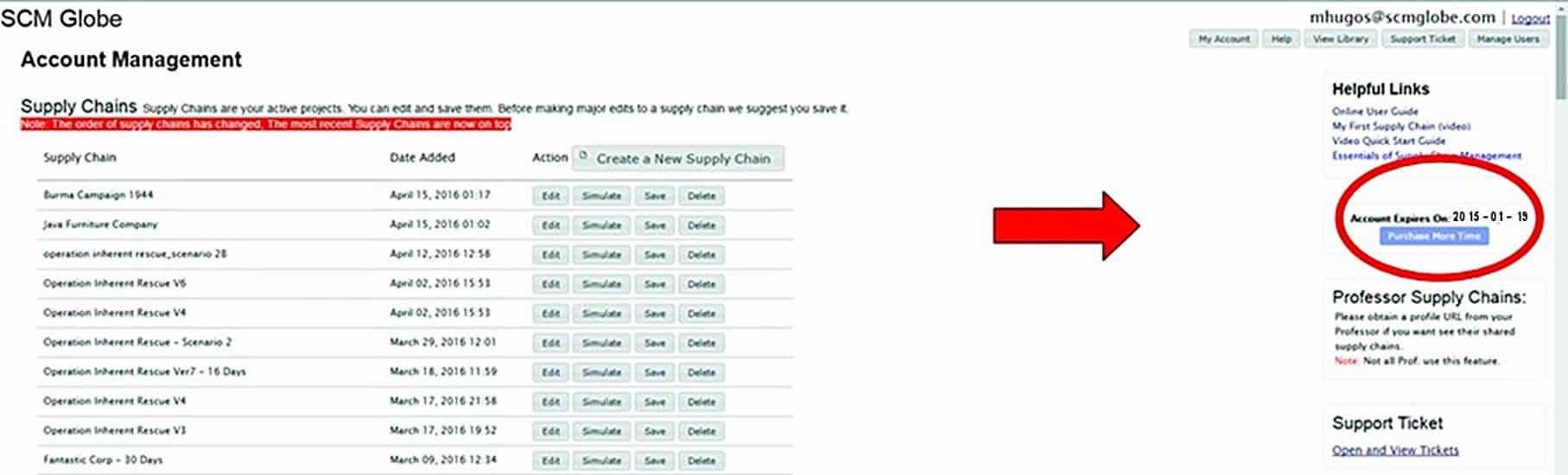

- Look on the right side of your account screen underneath "Helpful Links" as shown in screenshot below. Red arrow points to "Account Expires On:" see the expiration date of your subscription. If you want to buy more time on your account, then click the "Purchase More Time" button shown under the account expiration date. It will take you to the payment screen where you can buy more time.

- STUDENT ACCOUNTS DEFAULT TO 90 DAYS FROM DATE OF PURCHASE — if your semester is a few weeks longer, then send an email to: info@scmglobe.com. State your name, the email address you used to register, your school, and your semester end date. We can extend your account to cover your entire semester.

.

.- An instructor may request extended access if a student has an Incomplete for the course. The student must discuss their need with their instructor who will make the extension request if it is approved by the instructor.

- Flip back and forth between two browser tabs - Edit and Simulate. Once you run a simulation by clicking the “Simulation” button, you have two browser tabs open - one for editing, and one for simulating. Avoid opening additional browser tabs, don't need to click the "Simulation" button again, just click on the two existing browser tabs to navigate back and forth between editing your supply chain model and simulating its operation.

- Click the “Update” or “Save” button in the dialog box when you add new data or edit existing data for products, facilities, vehicles, and routes (always in the lower right corner of the dialog boxes).

- SAVE BACKUP COPIES of your supply chain model from time to time as you make changes. Then if a change doesn't work out, you can restore from a saved copy.

- Share your supply chain models (json files) with other SCM Globe users; see "“Download and Share Supply Chain Models”

- There is a SPREADSHEET REPORTING TEMPLATE you can use to analyze downloaded simulation data. Import your simulation data into the template and create monthly profit & loss reports as well as generate key performance indicators. See more about this in the online guide section “Analyzing Simulation Data” – scroll down to the heading titled “Download Simulation Data to Spreadsheet Reporting Templates”. The sample template is set up for the Cincinnati Seasonings company, but look at how the reports read the simulation data and you will see how to change the spreadsheet as needed to accommodate any case study.

NOTE: The academic version of SCM Globe supports supply chain models containing up to 15 – 20 products and a similar number of facilities, vehicles and routes. Models exceeding these limits will run slowly and experience other problems. See “Tips for Building Supply Chain Models” for ways to work with these limits and other useful techniques you will need when you build new supply chains or add new products, facilities, vehicles and/or routes to existing supply chains.